SMART FACTORY PARTNERS FOR INDUSTRIAL VISION SYSTEMS.

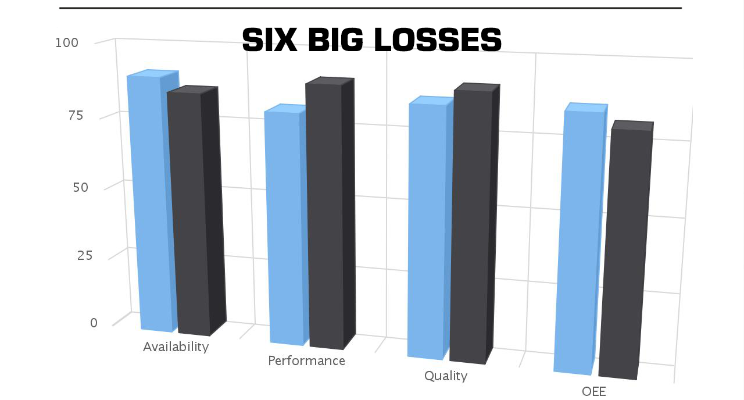

One of the major goals of OEE (Overall Equipment Effectiveness) programs is to reduce and/or eliminate what are called the Six Big Losses – the most common causes of efficiency loss in manufacturing.

A1Webcams can be added as a module to our overall Smart Factory Solution. When an event occurs causing machine downtime we attach a predefined timeline Video leading up to the event to the downtime analysis report which can be visualised on large centralised training and KPI operations screen.

The Line of Site System is a continuous monitoring solution that addresses all Six Big Losses. LSS kits are an excellent countermeasure tool to be used in addressing the Six Big Losses and have proven to be especially beneficial in root cause analysis, improving line efficiency, elimination of “short-stops,” and line speed increases. Plants have reported the technology paid for itself within the first few weeks of use on the plant floor. The vast majority of customers will no longer operate without LSS Continuous Monitoring Solution.

Overall Equipment Effectiveness Availability Performance Quality

Availability: The portion of the OEE Metric that represents the percentage of scheduled time that the operation is available to operate. Often referred to as Up time.

Planned Downtime: Every production line has several different procedures that could include planned downtime including product change over which could include tooling equipment changes, cleaning in between different materials and mixtures, and scheduled maintenance on hardware. Planned downtime is not included in the Availability calculation.

Breakdowns: Like every mechanical device in the world, every production line will eventually break down from unexpected circumstances. These normally include equipment/mechanical failures which cause starvation or blockages in other parts of the production line.

Performance: The portion of the OEE Metric that represents the speed at which the Work Centre runs as a percentage of its designed speed.

Idling and Minor Stoppages: Often there are technical failures that are on a very minor scale which could include small jams in product or equipment, blocked sensors or trapped products in the line. These are all considered minor stoppages and can easily add up to reduce the total OEE of the production line.

Speed Loss: Speed losses occur when a production line is not operating at the designed maximum operating speed. For instance, this can be when a bottling line is designed for 900 bottles per minute, but is operating at 600 bottles per minute because the labeling module is having minor technical problems when operating above 600.

Quality: The portion of the OEE Metric that represents the Good Units produced as a percentage of the Total Units Started Commonly referred to as the First Pass Yield (FPY).

Production Defects: This is losses based on products that do not meet specific quality standards and have to be scrapped or reworked.

Rejects on Start up: Startup losses are the losses that occur right at the beginning of a production line startup. Often the first products out of the production line are not up to par and have to be scrapped until production flow produces consistent quality products that meet the production standards.

MAPLE SUITE W/ DOWNTIME VIEWER

MAPLE Suite will provide you with powerful tools and key performance indicators (KPI) to increase efficiency and decrease downtime in your manufacturing operations. The MAPLE Suite system can connect multiple plants, sites and live production information, and integrate with equipment, controllers and enterprise business applications. The result is visibility, control and optimization of production and processes across the enterprise.

- Automated capture and tracking of equipment downtimes and production

- Highly configurable and adaptable to a multitude of operations

- Automatic determination of production line losses

- OEE Key Performance Indicators (KPI) dashboard and ad-hoc reporting

- User interface is optimized for touch-screen and efficient operator usability

- Integration with applications and equipment throughout the enterprise

- Standard web-based reporting package with automated/scheduled reports including scorecards and KPIs

A1 Webcam’s have perfected industrial vision camera systems and have built a reputation for over the last decade for being “dependable, reliable and affordable”. A1 Webcams Inc is currently in 29 Countries and 40 states within the United states. Their customer base includes many of the Fortune 100 manufacturing companies and they are committed to providing highly quality productivity camera solutions for automated manufacturing and lean production lines; delivering exceptional customer service with extensive product knowledge. Smart Factory are very proud to be the A1 chosen partners.